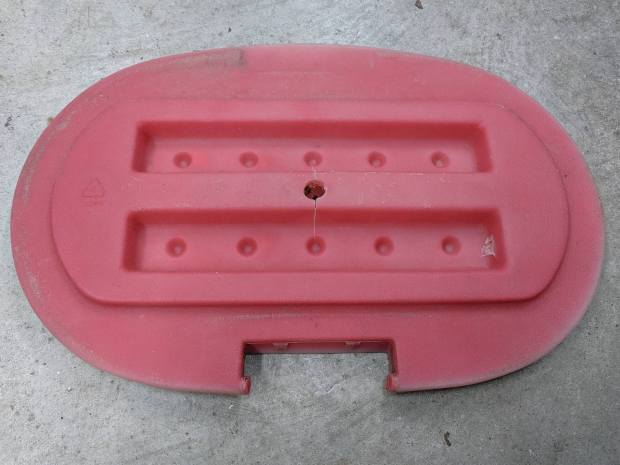

A pair of Step2 rolling garden seats (they have a new version) served in Mary’s gardens long enough to give their seat panels precarious cracks:

The underside was giving way, too:

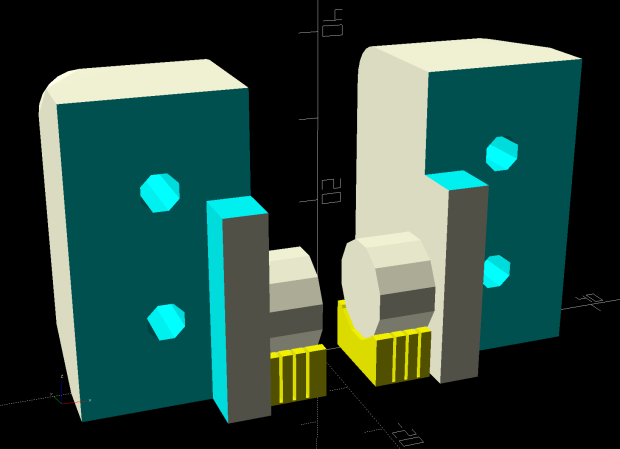

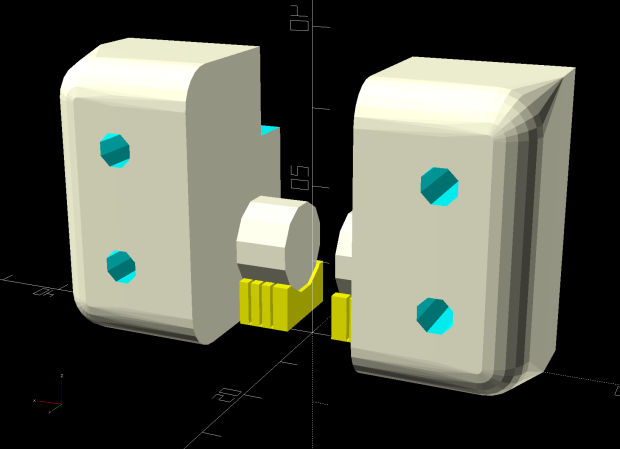

We agreed the new seat could be much simpler, although it must still hinge upward, so I conjured a pair of hinges from the vasty digital deep:

The woodpile disgorged a slab of 1/4 inch = 6 mm plywood (used in a defunct project) of just about the right size and we agreed a few holes wouldn’t be a problem for its projected ahem use case:

The screw holes on the hinge tops will let me run machine screws all the way through, should that be necessary. So far, a quartet of self-tapping sheet metal (!) screws are holding firm.

A closer look at the hinges in real life:

The solid model now caps the holes; I can drill them out should the need arise.

From the bottom:

Three coats of white exterior paint make it blindingly bright in the sun, although we expect a week or two in the garden will knock the shine right off:

After the first coat, I conjured a drying rack from a bamboo skewer, a cardboard flap, and some hot-melt glue:

Three small scars on the seat bottom were deemed acceptable.

The OpenSCAD source code as a GitHub Gist:

| // Hinge brackets for rolling garden stool | |

| // Ed Nisley - KE4ZNU - 2019-06 | |

| Layout = "Build"; // [Block,Build,Show] | |

| Support = true; | |

| /* [Hidden] */ | |

| ThreadThick = 0.20; | |

| ThreadWidth = 0.40; | |

| HoleWindage = 0.2; | |

| Protrusion = 0.1; // make holes end cleanly | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| //---------------------- | |

| // Dimensions | |

| SeatThick = 6.0; // seat panel above cart body | |

| HingePin = [11.5,12.0,7.0]; // ID = tip OD = base | |

| HingeOffset = 8.0; // hinge axis above cart body (larger than radius!) | |

| HingeBolster = [5.0,24.0,SeatThick]; // backing block below hinge | |

| Block = [25.0,HingeOffset + 30.0,23.0]; // Z = above cart body | |

| Screw = [3.8,11.0,2.5]; // self-tapping #8 OD=head LENGTH=head thickness | |

| ScrewOC = 15.0; // spacing > greater than head OD | |

| ScrewOffset = Block.y/2 - (ScrewOC/2 + Screw[OD]/2 + HingeOffset); // space for head behind hinge | |

| BlockRadius = 7.0; // corner rounding | |

| //---------------------- | |

| // Useful routines | |

| module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes | |

| Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); | |

| FixDia = Dia / cos(180/Sides); | |

| cylinder(r=(FixDia + HoleWindage)/2, | |

| h=Height, | |

| $fn=Sides); | |

| } | |

| // Basic block shape | |

| // X axis collinear with hinge axes, hinge base at X=0 | |

| module HingeBlock() { | |

| PinSides = 3*4; | |

| PinSupport = [HingePin[LENGTH] - 2*ThreadWidth,0.6*HingeOffset,HingePin[OD]]; // pre-rotated | |

| union() { | |

| translate([Protrusion,Block.y/2 - HingeOffset,HingeOffset]) | |

| rotate([0,-90,0]) | |

| rotate(180/PinSides) | |

| cylinder(d=HingePin[OD],h=HingePin[LENGTH] + Protrusion,$fn=PinSides); | |

| difference() { | |

| hull() { | |

| translate([Block.x - BlockRadius,-(Block.y/2 - BlockRadius),Block.z - BlockRadius]) | |

| rotate(180/PinSides) | |

| sphere(r=BlockRadius/cos(180/PinSides),$fn=PinSides); | |

| translate([0,-(Block.y/2 - BlockRadius),Block.z - BlockRadius]) | |

| rotate([0,90,0]) rotate(180/PinSides) | |

| cylinder(r=BlockRadius/cos(180/PinSides),h=Block.x/2,$fn=PinSides); | |

| translate([Block.x - BlockRadius,(Block.y/2 - BlockRadius),Block.z - BlockRadius]) | |

| sphere(r=BlockRadius/cos(180/PinSides),$fn=PinSides); | |

| translate([0,(Block.y/2 - BlockRadius),Block.z - BlockRadius]) | |

| rotate([0,90,0]) rotate(180/PinSides) | |

| cylinder(r=BlockRadius/cos(180/PinSides),h=Block.x/2,$fn=PinSides); | |

| translate([0,-Block.y/2,0]) | |

| cube([Block.x,Block.y - HingeOffset,Block.z/2],center=false); | |

| translate([0,Block.y/2 - HingeOffset,HingeOffset]) | |

| rotate([0,90,0]) rotate(180/PinSides) | |

| cylinder(r=HingeOffset/cos(180/PinSides),h=Block.x,$fn=PinSides); | |

| } | |

| translate([Block.x/2 + HingeBolster.x,0,(SeatThick - Protrusion)/2]) | |

| cube([Block.x,2*Block.y,SeatThick + Protrusion],center=true); | |

| translate([0,-HingeBolster.y,(SeatThick - Protrusion)/2]) | |

| cube([3*Block.x,Block.y,SeatThick + Protrusion],center=true); | |

| for (j=[-1,1]) | |

| translate([Block.x/2,j*ScrewOC/2 + ScrewOffset,-4*ThreadThick]) | |

| rotate(180/8) | |

| PolyCyl(Screw[ID],Block.z,8); | |

| } | |

| } | |

| if (Support) { // totally ad-hoc | |

| color("Yellow") render(convexity=4) | |

| difference() { | |

| translate([-(PinSupport.x/2 + 2*ThreadWidth),Block.y/2 - PinSupport.y/2,HingeOffset]) | |

| cube(PinSupport,center=true); | |

| translate([Protrusion,Block.y/2 - HingeOffset,HingeOffset]) | |

| rotate([0,-90,0]) | |

| rotate(180/PinSides) | |

| cylinder(d=HingePin[OD] + 2*ThreadThick,h=2*HingePin[LENGTH],$fn=PinSides); | |

| for (i=[-1:1]) | |

| translate([i*4*ThreadWidth - HingePin[LENGTH]/2, | |

| Block.y/2 - (PinSupport.y + 1*ThreadThick), | |

| HingeOffset]) | |

| cube([2*ThreadWidth,2*PinSupport.y,2*PinSupport.z],center=true); | |

| } | |

| } | |

| } | |

| module Blocks(Hand = "Left") { | |

| if (Hand == "Left") | |

| HingeBlock(); | |

| else | |

| mirror([1,0,0]) | |

| HingeBlock(); | |

| } | |

| //- Build it | |

| if (Layout == "Block") | |

| HingeBlock(); | |

| if (Layout == "Show") { | |

| translate([1.5*HingePin[LENGTH],0,0]) | |

| Blocks("Left"); | |

| translate([-1.5*HingePin[LENGTH],0,0]) | |

| Blocks("Right"); | |

| } | |

| if (Layout == "Build") { | |

| translate([0,-Block.z/2,Block.y/2]) | |

| rotate([-90,0,0]) { | |

| translate([1.5*HingePin[LENGTH],0,0]) | |

| Blocks("Left"); | |

| translate([-1.5*HingePin[LENGTH],0,0]) | |

| Blocks("Right"); | |

| } | |

| } |

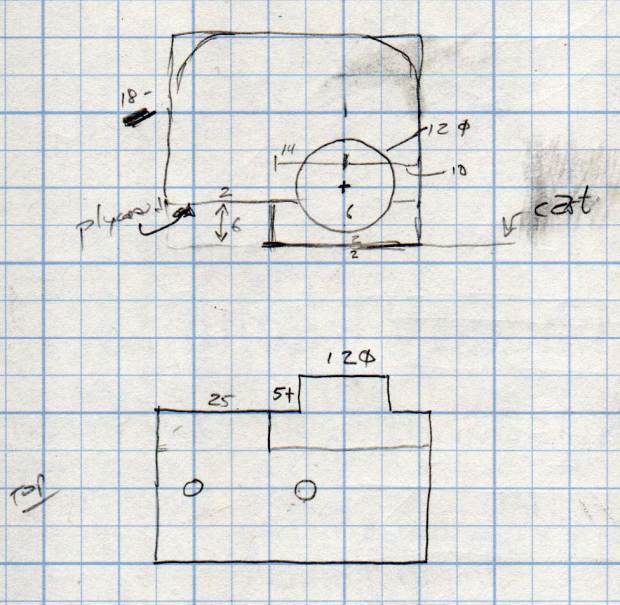

This original doodle gives the key dimensions, apart from the rounded rear edge required so the seat can pivot vertically upward:

The second seat looks just like this one, so life is good …